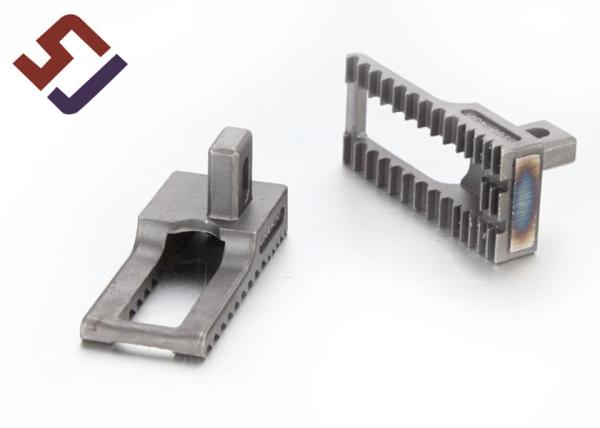

Part Name:Tool gears , precision investment castings for toolings

Main Process For Steel Casting

Investment casting (wax mold made by middle temperature wax);

Lost Wax Casting (wax mold made by low temperature wax);

General Products Application /Service Area

Metal Parts Solution for Vehicle, Agriculture machine, Construction

Machine, transportation equipment, Valve and Pump system. E.g.

Engine bracket, truck chassis bracket, gear box , gear housing ,

gear cover, shaft, spline shaft , pulley, flange, connection pipe,

pipe, hydraulic valve , valve housing ,Fitting , flange, wheel,

flywheel, oil pump housing, starter housing, coolant pump housing,

transmission shaft , transmission gear, sprocket, chains etc.

Description:

| Material | carbon steel |

| Process | investment precision casting process |

| Part weight | 0.02-0.3KG |

| Packaging Details | Packed with anti-corrosion rust paper and bubble paper to

pretension ,big rust big and wood box and stick the label |

| Supply Capacity | 3,0000-50000pcs per month |

| Tolerance of rough casting | ISO8062 CT4-CT6 |

| Used for | hydraulic parts |

Application Information:

Auto, motorcycle, valve, marine, machine tools, hardware, railway,

gear, impeller, pump, reducer, motor, mining machinery, engineering

machinery, transmission machinery, forestry machinery, communal

facility, etc.

Precision castings Parts for kinds of machinery

1. Material: Stainless steel/1.4308 (CF8), 1.4408 (CF8M), 1.4301

(SS304), 1.4401 (SS316), and 1.4404 (SS316L) 17-4PH,Cr25Ni20,

Carbon steel,WCB etc.Process: Investment Casting, Die Casting, Sand

Casting, Stamping, CNC Machining is available

2. Surface finish: Zinc/Nickel/Chrome Plating(color or natural),

Galvanization, Anodizing, Hard Anodizing, Oil Spraying, Powder

Coating, Polishing, Passivate, Brush, Wire drawing, etc.

Our invertment precision casting

Process flow:

Wax Injection--Make Wax pattern and repair--Inspection--Shell

Making--De-waxing--Roasting Shell and Melting Steel--Composition

Inspection--Pouring--De shelling--Cutting and Grinding the pouring

gate--Inspection--Heat

treatment--Shotblasting--Machining--Anti-Corrosion--Final

Inspection--Shipping

Precision Casting

Part Packing

Our Company

Our

Precision Casting Manufacturing Process