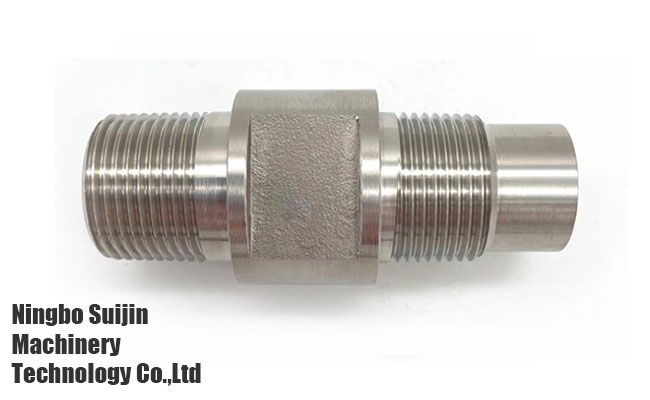

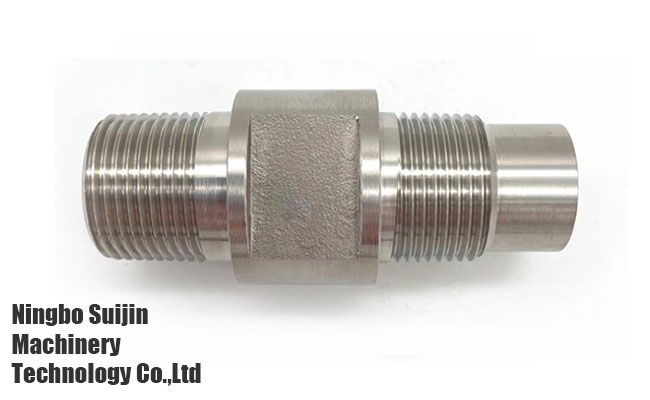

OEM Alloy Pipe Fitting Investment Casting Stainless Steel 316 CNC

Metal Casting

Ningbo Suijin can supply different kinds of pipe fittings used in

piping systems. suche asd elbows, tees, reducers, unions,

couplings, crosses, caps, swage nipples, plugs, bushings, adapters,

outlets, valves & flanges.These pipe fittings can be found in

various pressure classes , We also different forged carbon steel

fittings.Pipe fittings are used to join pipes together. Component

of the piping system that aids in Elbows and tees change the flow

direction. Reducers and reducing tees change the pipe’s size.

Various parts, like couplings, are used to connect and stop flows.

We adopt all-silica sol dewaxing precision casting, paraffin

investment precision casting, die casting and other processes,

specializing in the production of precision castings and products

of various materials.

Ningbo Suijin can cast various hardware thin-walled parts for

customers, which are light in weight and complex in shape. Widely

used in hardware tools, machinery manufacturing and machining

industries, and in the shipping sector are grades, aviation

products, auto parts, water pumps, pneumatic tool accessories,

lighting hardware, valves, architectural hardware, lock

accessories, valve castings, door hinges, Stair handrail

accessories, pipe joints, etc., and can support casting, heat

treatment, shot blasting, gross machining services according to

customer requirements.

Hardware Castings details

| Product Name | Pipe Fitting Hardware Castings |

| Processed | Silicon Casting and Machining |

| Material | SUS 430 |

| Weight | 0.3-0.8 kg |

| Application | Exhaust system |

| Casting tolerance | Investment casting ISO 8062-3 DCTG 5 |

| Casting Surface condition | Ra3.2 um |

| Surface treatment | None |

| Brand | Ningbo Suijin |

Hardware Castings Picture show

Our Quality control

1) We possess a large scale of foundry and CNC machines, as well as

production lines of lost wax casting to cater to the need of

growing precision investment casting business. Besides, we have

advanced inspecting instruments such as Spectrometer,

Metallographic Microscope, Tension Tester, and Impact tester for

Chemical & Physical Analysis, and 2D projector, X-ray, Ultrasonic ,

magnetic to keep inner good instruction, CMM to assure dimensional

precision.

2) Quality control starts the minute the precision investment

casting raw material arrives the foundry, continues along with

every stage of investment casting process. We were awarded with

ISO9001:2000 by SGS, PED/AD2000 by TUV.

3) We have developed and manufactured more than 3300 types of

precision investment casting products, which are widely applied in

Auto Parts, Construction Hardware, Marine Hardware, Pumps & Valves,

Machine Parts and other industries. A large percentage of our

investment casting parts were exported to Europe, US, Japan and

Asia.

Process flow:

Wax Injection--Make Wax pattern and repair--Inspection--Shell

Making--De-waxing--Roasting Shell and Melting Steel--Composition

Inspection--Pouring--De shelling--Cutting and Grinding the pouring

gate--Inspection--Heat

treatment--Shotblasting--Machining--Anti-Corrosion--Final

Inspection--Shipping

Precision Casting

Part Packing

Our Company

Competitive Advantage:

1 . All of our products are strictly inspected and tested before

packing in factory..

2 . Good team for quality and delivery time control.

3 . Close to Ningbo Port and Shanghai Port.

4 . We have a team of professional engineers to supply related

technology help if customers need our tech-assistant.

5. Good Projects and PPAP documents experience

6: Full APQP process to control the quality

Our

Precision Casting Manufacturing Process