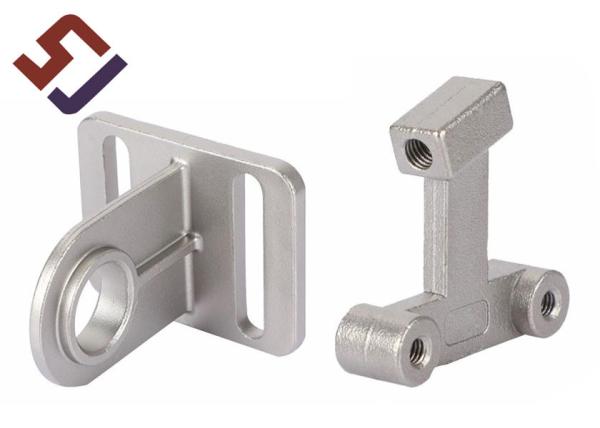

Founded in 2003, Ningbo Suijin Machinery Technology is

located in Ningbo city ,Zhejiang Province, We manufactured all

kinds of lost wax investment castings and machining parts or called

precision investment castings , material including carbon steel,

alloy steel, and stainless steel. we also can according to the

customers' requirement to compound the material, Our factory has a

floor space of 33,000 square meters and another 18000 square meters

of building area, which contain both casting foundries and CNC

machining area. The two advanced lost wax casting and investment

casting production lines have a capacity of 5000 tons lost wax

castings and 1000 tons investment castings per year.

To keep the good quality parts we had set up our lab center which

is advance center in our area. Our inspection equipments includes

Spectrometer, Metallographic Microscope, Tension Tester, Low

Temperature Impact tester, X-ray tester, magnetic particle

detector, UT, CMM, and so on. every year we will investment to buy

more equipments to develop our business.

We supply parts in a wide range in industries that includes

automotive, boats, Oil machinery, agricultural machinery, building

equipment, valves, pumps, electrical machinery, hardware,

transmission, etc. we have produced more than 1000 different

productions. more than 95% are exported to America, Canada, France,

Germany, Denmark, Britain, Japan, etc.

Our company has more than 300 employees, including 17 engineers and

15 QC. every year some of employees will out training to improve

their knowledges and skills. we had got ISO/TS16949:2009 and PED

certifications.

We strive to provide the best quality and service while maintaining

the basic principles of respect and honesty. We sincerely invite

global customers to visit our company, and hope to establish a long

term business relationship